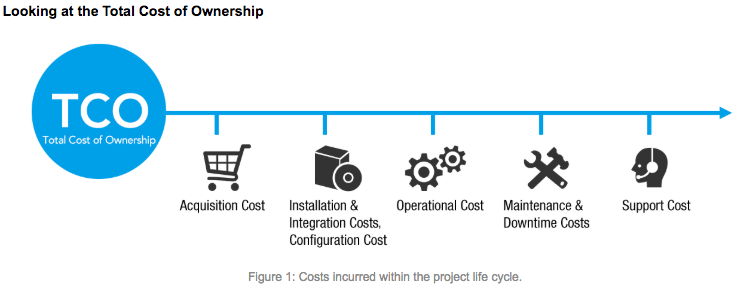

The Industrial IoT trend has brought about a remarkable increase in connected devices on networks as well as increased the scope and complexity of industrial control networks that frequently converge with traditional IT networks. Due to this significant change, network operators are starting to notice that simply purchasing devices for networks isn’t the end of their expenditure. In fact, it is often only the beginning.

Some of the general steps involved in installing, integrating, commissioning, operating, and supporting an industrial network will now be considered in order to gain a better understanding of the TCO. In addition, some best practices and tips on how to lower the TCO for industrial control networks will also be considered.

Tip 1: Reduce Installation Costs for Control Panels

On industrial networks, devices are often installed in control panels with other devices that run on different voltages, so one solution is to purchase a power converter to ensure compatibility. However, this may not be the ideal solution for all network administrators due to size constraints of the panel where the devices are being installed or the additional costs incurred from purchasing power converters. For some projects, the cost of deploying new cables can add significantly to the overall costs of the project. A better alternative is to use a device that supports a wide range of power inputs that will satisfy the present demands of the network, and provide added flexibility for devices that must also be added to the network at a later date.

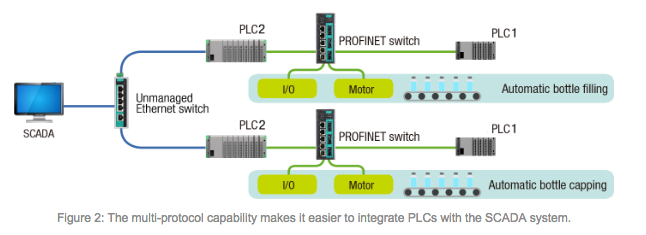

Tip 2: Reduce Configuration Costs for Protocol Integration to SCADA Systems

Due to the convergence of industrial automation and IT systems across IIoT networks, EtherNet/IP and PROFINET protocols must have a way to operate together on the same network. Devices that have been preconfigured to allow for these disparate protocols to communicate automatically, allow network administrators to deploy what is essentially a plug-and-play device. These devices will also often support automatic discovery and the ability to assign IP addresses automatically, allowing a significant portion of the time required for configuring these devices to be eliminated. This can be compared with using cheaper devices, which will require a lot more effort to be spent configuring the devices later on in the project.

Best Practice: Reduce Costs through Network Management Tools

Batch configuration is one of the most effective ways to reduce configuration costs through network management tools. Since the number of devices on networks keeps increasing, both time and money can be saved by using mass configuration, instead of configuring devices one-by-one. Being able to view the current status of the network at a quick glance via software or an app is one of the easiest ways to monitor a network. Another benefit that network management tools provide is to reduce maintenance costs by enabling real-time event notifications via email or mobile apps. These apps and software sometimes incorporate an alert system that warns network administrators that an event is taking place that has the potential to cause a failure on the network unless the problem is rectified.

For more tips and best practices, please download the white paper Six Tips on How to Lower the Total Cost of Ownership of Industrial IoT Networks.